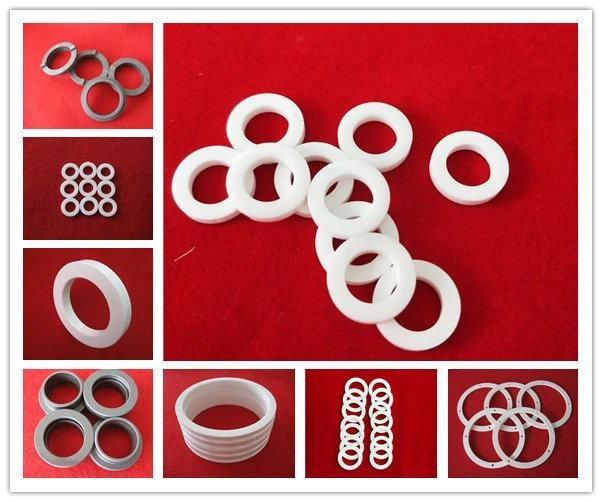

Products descirbe

Application

You May Like

Delivery & Packing

Zirconia Industrial Ceramic

Zirconia is a material with very high resistance to crack propagation. And its fine grain size enables excellent surface finishes and the ability to hold a sharp edge. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. Zirconium oxide ceramics are used among other applications, as tools for wire forming, as auxiliaries in welding processes, as materials for crowns and bridges in the dental industry, as insulating rings in thermal processes, and as oxygen measurement cells in lambda probes.Technical data

| Properties(Zirconia) | Units | Value |

| Density, r | g/cm3 | 6.04 |

| Color | - | white |

| Water Absorption | % @R.T. | 0.0 |

| Hardness | Moh's | 6.5 |

| Hardness | knoop (kg/mm2) | 1600 |

| Compressive Strength | MPa @ R.T. | 2500 |

| Tensile Strength | MPa @ R.T. | 248 |

| Modulus of Elasticity(Young's Mod.) | GPa | 207 |

| Flexural Strength (MOR) | MPa @ R.T. | 900 |

| Fracture Toughness, KIc | MPa x m1/2 | 13.0 |

| Max. Use Temperature(* denotes inert atm.) | ºC | 500-1600 |

| Thermal Shock Resistance | DT (ºC) | 280 - 360 |

| Thermal Conductivity | W/m-K @ R.T. | 2.7 |

| Coefficient of Linear Thermal Expansion | mm/m-ºC (~25ºC through ±1000ºC) | 11.0 |

| Specific Heat, cp | cal/g-ºC @ R.T. | 0.10 |

| Dielectric Constant | 1MHz @ R.T. | 26 @100kHz |

| Dielectric Strength | kV/mm | 9.0 |

| Electrical Resistivity | Wcm @ R.T. | >1013 |

Product Detail

Application

In functional ceramics, its excellent high-temperature performance as induction heating tube, refractory material, heating element used. Zirconia ceramics with electrical parameters sensitive, mainly used in oxygen sensors and solid oxide fuel cell (Solid Oxide Fuel Cell, SOFC) and high temperature heating index field of.ZrO2 has a higher rate of (N-21^22), add some coloring elements in zirconium oxide superfine powder in (V2O5, MoO3, Fe2O3 etc.), it can be made of colorful translucent polycrystalline ZrO2 material, like natural stones as bright and colorful flashing light, can be made into various decorations. In addition, the zirconia thermal barrier coating, catalyst carrier, medical, health care, refractory materials, textile and other fields are widely used.

Our Services

1.Customized component;

2.Sample order

3.We will reply you for your inquiry in 24 hours.

4.Hot &dry pressing,injection, Iso-static,coating etc.

When you got the machinable ceramic products, test them, and give me a feedback.If you have any questions about the problem, contact with us.

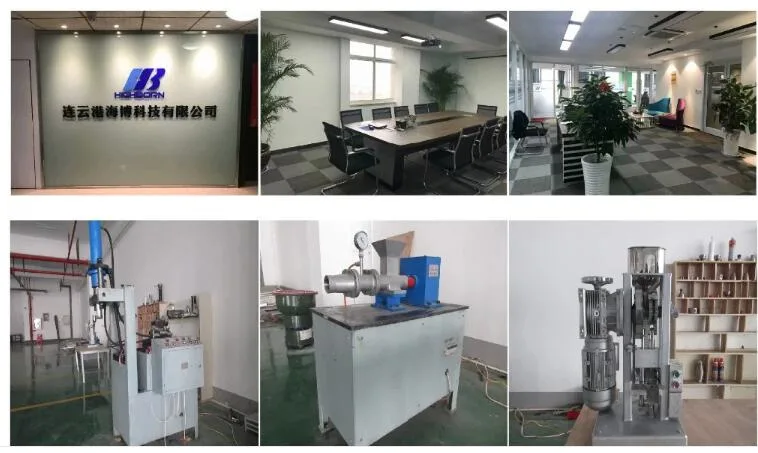

Our Company

Our ceramic products are widely used in various fields of automotive, metallurgy, machinery, electronic & electrical, food, chemical, medical and so on. With experienced engineers and talented workers, we are able to evaluate projects and drawings properly, make valuable suggestion, supply satisfying products.

Our products' material include alumina, zirconia, corundum mullite ,silicon nitride, aluminum nitride, silicon carbide and so on, and expressly, our price is very competitive because we have manufactory.

1.Customized component;

2.Sample order

3.We will reply you for your inquiry in 24 hours.

4.Hot &dry pressing,injection, Iso-static,coating etc.

When you got the machinable ceramic products, test them, and give me a feedback.If you have any questions about the problem, contact with us.

Our Company

Our ceramic products are widely used in various fields of automotive, metallurgy, machinery, electronic & electrical, food, chemical, medical and so on. With experienced engineers and talented workers, we are able to evaluate projects and drawings properly, make valuable suggestion, supply satisfying products.

Our products' material include alumina, zirconia, corundum mullite ,silicon nitride, aluminum nitride, silicon carbide and so on, and expressly, our price is very competitive because we have manufactory.

You May Like

Delivery & Packing

FAQ

1.Where is your main market?

We have been exported to USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc, so far, there is about 151 countries we have been exported, we also get good reputation from our customers.

2. What is your payment term?

We mainly accept T/T, West Union, Credit card and L/C.

Paypal will be available in the near future.

3. For zirconia ceramic, what about the forming method?

Drying pressing

Isostatic pressing

Hot pressing casting

4.What about the package?

We pack with plastic bubble paper, carton box, then safe wooden box outside, we can control the breakage less than 1%.

1.Where is your main market?

We have been exported to USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc, so far, there is about 151 countries we have been exported, we also get good reputation from our customers.

2. What is your payment term?

We mainly accept T/T, West Union, Credit card and L/C.

Paypal will be available in the near future.

3. For zirconia ceramic, what about the forming method?

Drying pressing

Isostatic pressing

Hot pressing casting

4.What about the package?

We pack with plastic bubble paper, carton box, then safe wooden box outside, we can control the breakage less than 1%.

IF YOU HAVE ANY QUESTIONS,PLEASE CONTACT ME,I WILL REPLY ASAP.