1: Product Details

Alloy 316/316L (UNS S31600/S31603) is a chromium-nickelmolybdenum austenitic stainless steel developed to provide

improved corrosion resistance to Alloy 304/304L in moderately corrosive environments. It is often utilized in process streams

containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance.

It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures.

It is common practice for 316L to be dual certified as 316 and 316L. The low carbon chemistry of 316L combined with an

addition of nitrogen enables 316L to meet the mechanical properties of 316.

Alloy 316/316L resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists

corrosion in polluted marine atmospheres. The alloy has excellent resistance to intergranular corrosion in the as-welded

condition. Alloy 316/316L has excellent strength and toughness at cryogenic temperatures.

Alloy 316/316L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or

welding. It can be easily welded and processed by standard shop fabrication practices.

In most applications Alloy 316/316L has superior corrosion resistance to Alloy 304/304L. Process environments that do not c

orrode Alloy 304/304L will not attack this grade. One exception, however, is in highly oxidizing acids such as nitric acid where

stainless steels containing molybdenum are less resistant. Alloy 316/316L performs well in sulfur containing service such as

that encountered in the pulp and paper industry. The alloy can be used in high concentrations at temperatures up to 120°F (38°C).

Alloy 316/316L also has good resistance to pitting in phosphoric and acetic acid. It performs well in boiling 20% phosphoric acid.

The alloy can also be used in the food and pharmaceutical process industries where it is utilized to handle hot organic and fatty

acids in an effort to minimize product contamination.

Alloy 316/316L performs well in fresh water service even with high levels of chlorides. The alloy has excellent resistance to

corrosion in marine environments under atmospheric conditions.

The higher molybdenum content of Alloy 316/316L assures it will have superior pitting resistance to Alloy 304/304L in applications

involving chloride solutions, particularly in an oxidizing environment.

In most instances, the corrosion resistance of Alloys 316 and 316L will be roughly equal in most corrosive environments.

However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones

Alloy 316L should be used because of its low carbon content.

2: Chemical Composition

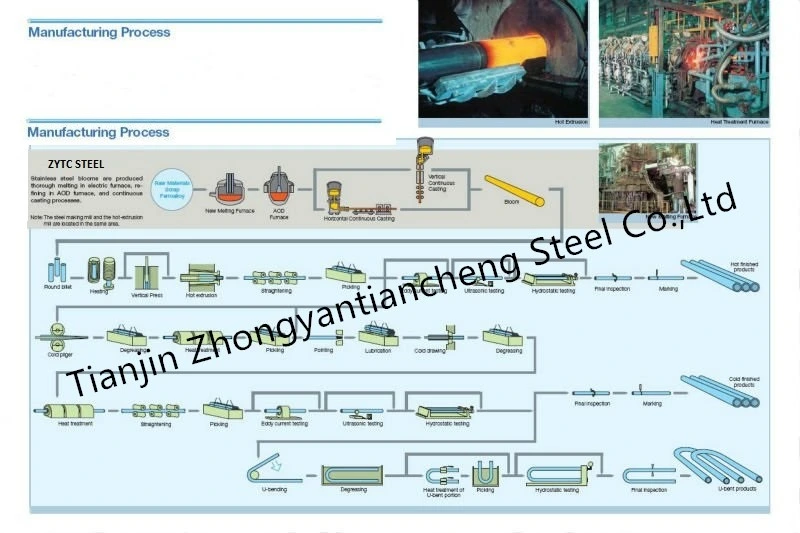

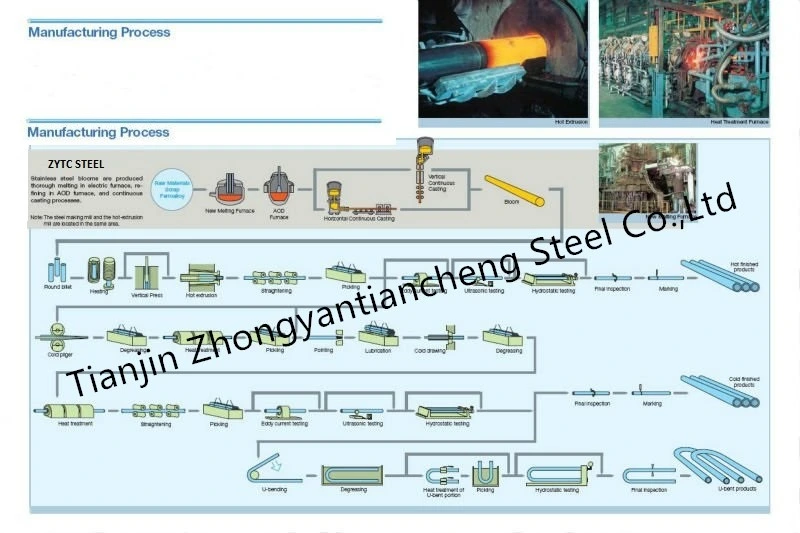

3: Stainless Steel Seamless Pipe Or Welded Pipe Process

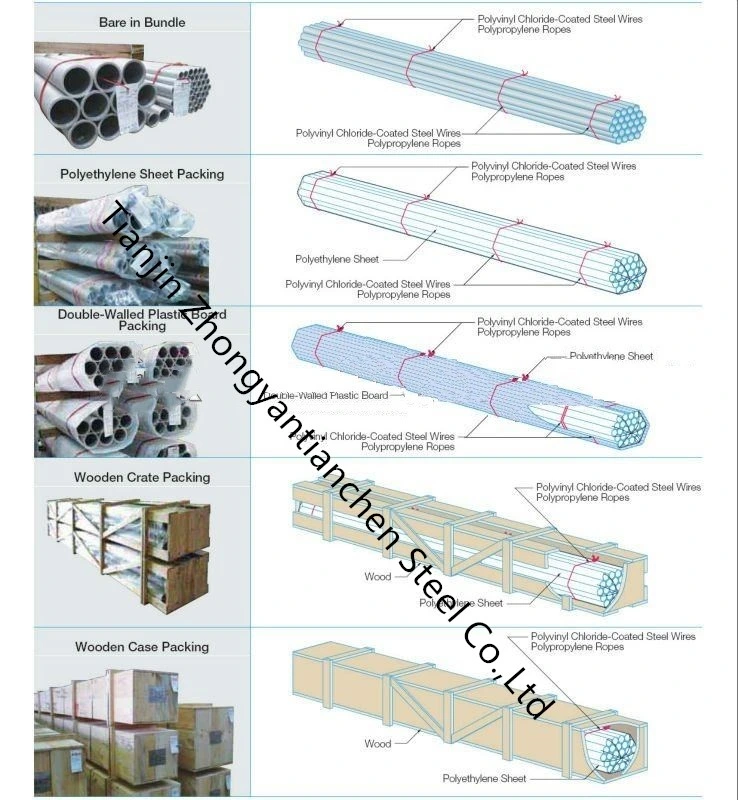

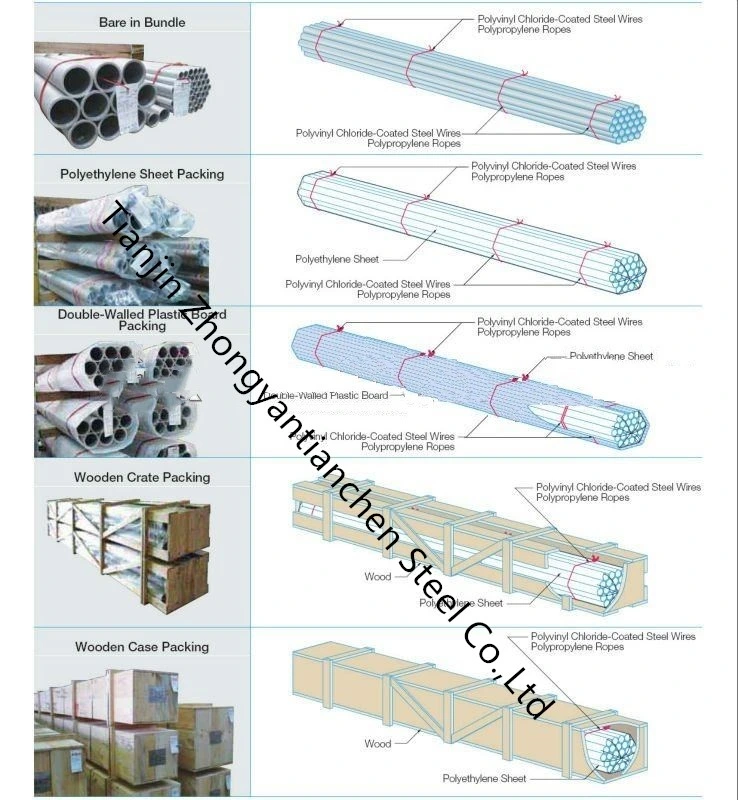

4: Stainless Steel Seamless Or Welded Pipe Package

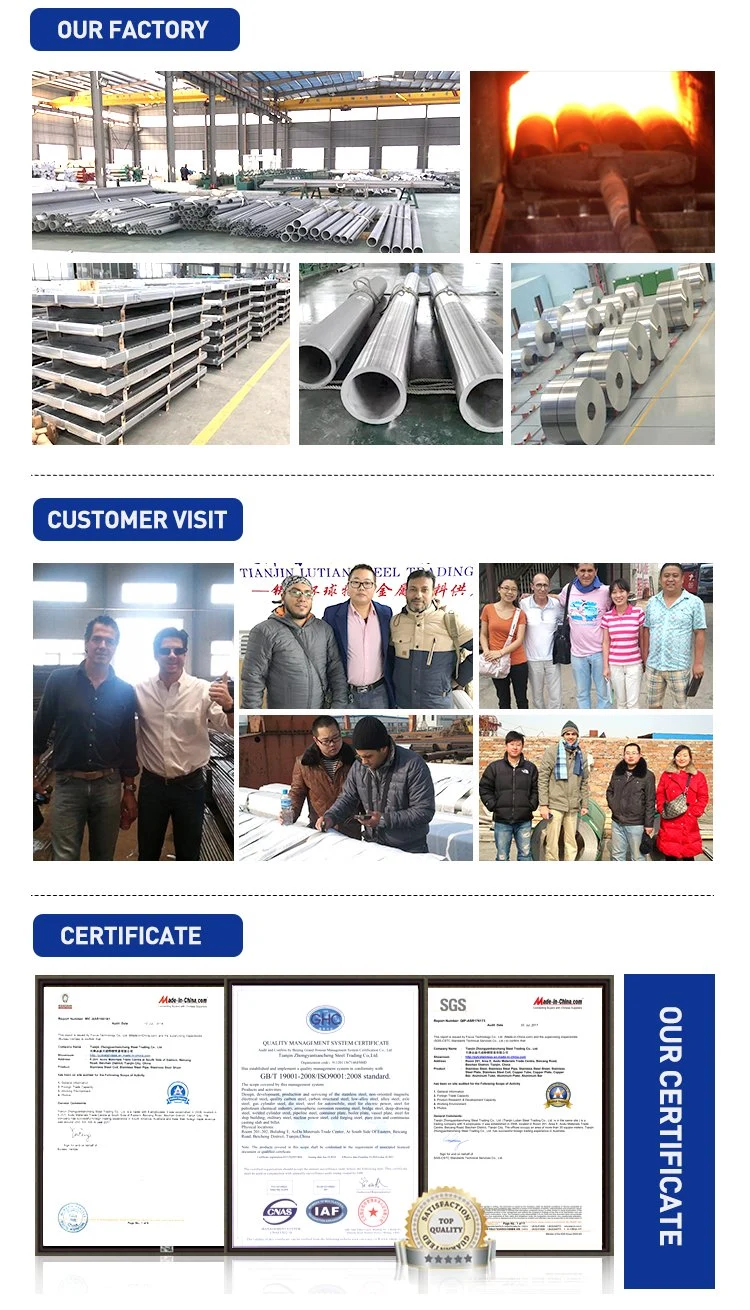

5: Company Introduction

6: Contact Us

Alloy 316/316L (UNS S31600/S31603) is a chromium-nickelmolybdenum austenitic stainless steel developed to provide

improved corrosion resistance to Alloy 304/304L in moderately corrosive environments. It is often utilized in process streams

containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance.

It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures.

It is common practice for 316L to be dual certified as 316 and 316L. The low carbon chemistry of 316L combined with an

addition of nitrogen enables 316L to meet the mechanical properties of 316.

Alloy 316/316L resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists

corrosion in polluted marine atmospheres. The alloy has excellent resistance to intergranular corrosion in the as-welded

condition. Alloy 316/316L has excellent strength and toughness at cryogenic temperatures.

Alloy 316/316L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or

welding. It can be easily welded and processed by standard shop fabrication practices.

In most applications Alloy 316/316L has superior corrosion resistance to Alloy 304/304L. Process environments that do not c

orrode Alloy 304/304L will not attack this grade. One exception, however, is in highly oxidizing acids such as nitric acid where

stainless steels containing molybdenum are less resistant. Alloy 316/316L performs well in sulfur containing service such as

that encountered in the pulp and paper industry. The alloy can be used in high concentrations at temperatures up to 120°F (38°C).

Alloy 316/316L also has good resistance to pitting in phosphoric and acetic acid. It performs well in boiling 20% phosphoric acid.

The alloy can also be used in the food and pharmaceutical process industries where it is utilized to handle hot organic and fatty

acids in an effort to minimize product contamination.

Alloy 316/316L performs well in fresh water service even with high levels of chlorides. The alloy has excellent resistance to

corrosion in marine environments under atmospheric conditions.

The higher molybdenum content of Alloy 316/316L assures it will have superior pitting resistance to Alloy 304/304L in applications

involving chloride solutions, particularly in an oxidizing environment.

In most instances, the corrosion resistance of Alloys 316 and 316L will be roughly equal in most corrosive environments.

However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones

Alloy 316L should be used because of its low carbon content.

2: Chemical Composition

| Tianjin Zhongyantiancheng Steel Co.,Ltd | ||||

| Commodity | Stainless Steel Pipe/Welded Steel Tube/Seamless Steel Pipe | |||

| Material | 316L | |||

| Standard | GB | JIS | ASTM/ASME | DIN |

| 022Cr17Ni12Mo2 | SUS316L | 316L | 1.4401 | |

| Chemical Composition | C | Mn | P | S |

| <=0.03 | <=2.00 | <=0.045 | <=0.03 | |

| Si | Cr | Mo | Ni | |

| <=0.75 | 16--18 | 2--3 | 10--14 | |

| Outside Diameter | 4mm--720mm | |||

| Thickness | 0.5mm-68mm | |||

| Length | Produce as customers' request | |||

| Surface | Black/Bright | |||

| manufacture | Hot Rolled/Cold Drawn | |||

| Packing | Packed in bundles with standard export sea-worthy package | |||

| Delivery Time | Within 15 working days, according to customers' quantities | |||

| Quality | High Quality.SGS inspection is accepted if needed | |||

| Place of Origin | Tianjin | |||

| Productivity | 500 MT/Month | |||

| Payment | T/T,L/C | |||

| MOQ | 1 MT | |||

| Application | Foodstuff, Gas, metallurgy, biology, electron, chemical etc. | |||

| Note | We can also do other materials | |||

3: Stainless Steel Seamless Pipe Or Welded Pipe Process

4: Stainless Steel Seamless Or Welded Pipe Package

5: Company Introduction

6: Contact Us